Photo Materials

Photo Resist

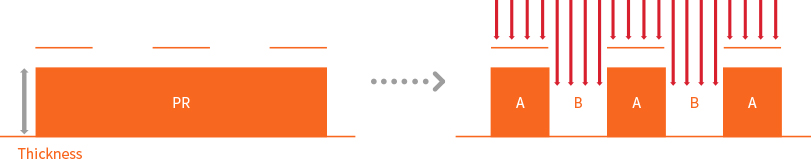

It is a material that forms an image pattern by causing a change in solubility in the developer when exposed to light and radiation energy, and it is a liquid material composed of polymers, photosensitizers, additives, and solvents.

Types of Photo Resist

- According to the wavelength of the light source, it is divided into I-line(about 365nm), KrF(248nm), ArF(193nm), and EUV(13.5nm), and the narrower the width of the wavelength, the more micro circuits can be drawn.

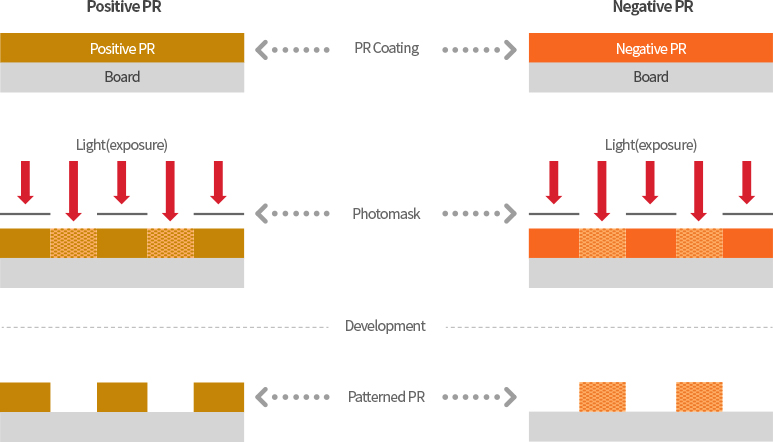

- It can be divided into Positive PR, in which the area exposed to light melts, and Negative PR, in which the area that is not exposed melts.

- SKMP is a material used in the photolithography process in the production of semiconductors for DRAM and NAND. We have various product lines from and ArF Imm PR to high-thickness bump PR for post-processing, and are developing EUV PR products according to advancement and refinement of semiconductor technology.

Photo Resist (PR) Types and Characteristics

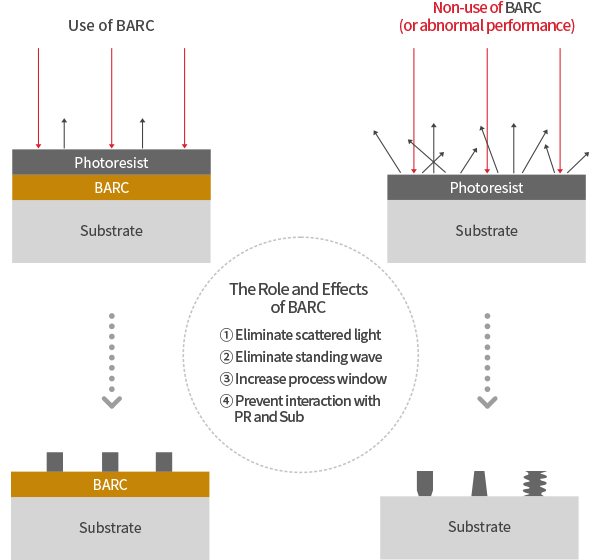

Bottom Layer Anti-Reflection Coating(BARC)

It is a material that minimizes the loss to pattern profile by suppressing the scattering and reflection of light from the substrate generated during the exposure process. SKMP's BARC products have an excellent coating, ranging from ArF Imm BARC to KrF BARC, and a high refractive index(n) that allows to achieve physical properties with minimal thickness.

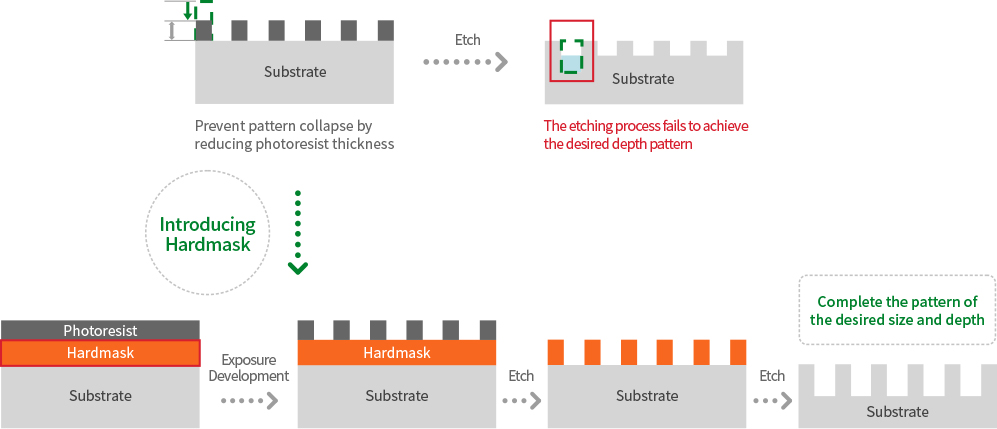

Hardmask(SOC)

As the thickness of the PR becomes thinner and the size of the pattern becomes smaller due to the high integration

of the semiconductor, the collapse of the PR pattern occurs. Therefore, it is not possible to etch the layer using the

PR pattern, so the hardmask (SOC), a representative material with strong etching resistance, is introduced between

the PR and the layer to be etched.

SKMP's SOC products with strong etching resistance and flattening characteristics range from 400 Å to 3 μm thickness,

and we are developing excellent SOCs that meet the characteristics of process according to customers and the development

of semiconductor technology.